Ultrasonic technology today plays a far greater role in our lives and industries than most people realize — from medical equipment to production machinery and even industrial cleaning systems.

This article provides a concise and clear overview of the essence and main applications of ultrasonic technology — without delving into complex engineering details. The goal is simple: to understand what ultrasonx are, how they work, and why they have become vital to so many modern industries.

Table of Contents

TogglePrinciple of Ultrasonic Technology

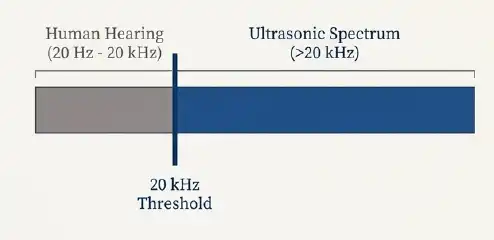

The term “ultrasonic” refers to sound waves with frequencies higher than the human hearing threshold — typically above 20 kHz. Ultrasonic devices generate these high-frequency sound waves to act upon materials or components.

The core mechanism is the conversion of electrical energy into mechanical vibration. This conversion is achieved through components known as piezoelectric transducers (Piezos). When an electric signal is applied, the piezo element oscillates rapidly, producing ultrasonic vibrations that are transmitted into the target material.

In essence, it works much like a mobile phone’s vibration motor — but at vastly greater speed and power, and for precisely engineered purposes.

Main Components of an Ultrasonic System

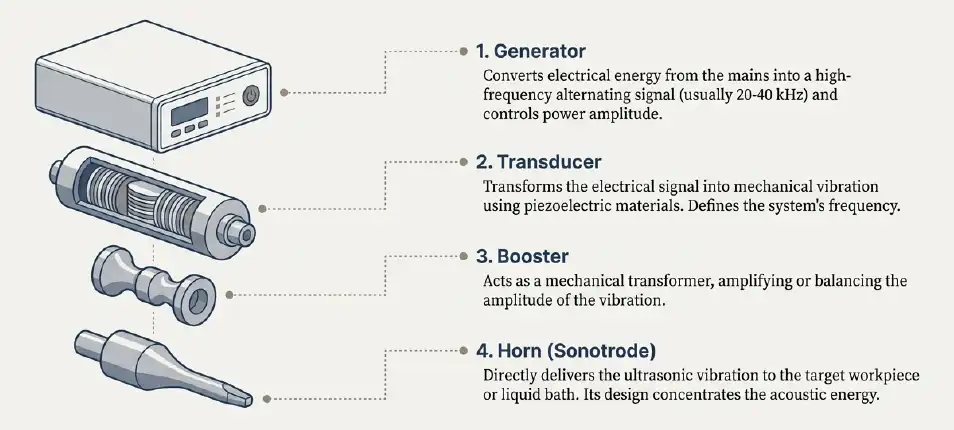

An industrial ultrasonx system generally comprises three key elements:

- Generator – produces the high-frequency electrical signal.

- Transducer – converts the electrical energy into acoustic energy.

- Booster and Horn – amplify and focus the sound waves onto the target area.

Together, these components deliver precise and uniform acoustic energy transfer for diverse industrial processes.

Major Industrial Applications of Ultrasonic Technology

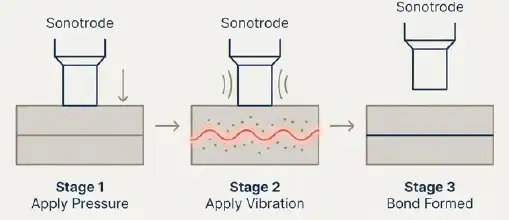

a) Ultrasonx Welding

Used for joining plastic and even metal components using high-frequency vibrations — eliminating the need for external heat or adhesives.

b) Ultrasonic Cutting and Pressing

Ideal for precision processing of delicate or multilayer materials such as textiles, films, and electronic parts, ensuring smooth and burr-free edges.

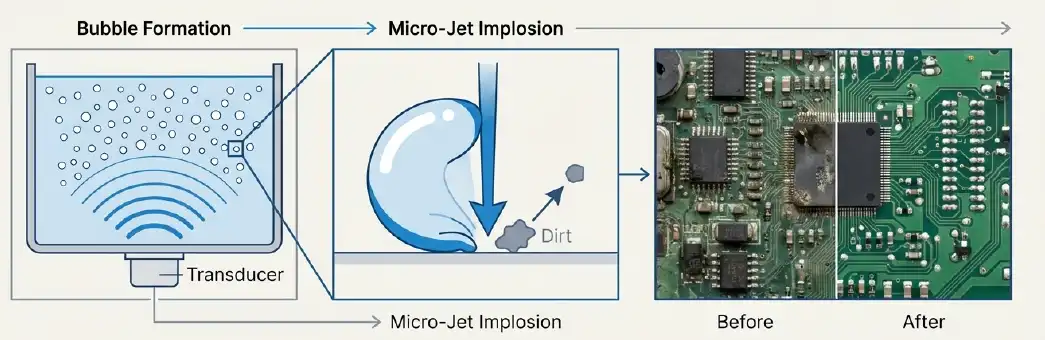

c) Ultrasonx Cleaning

Tiny objects such as jewelry, automotive components, or medical instruments are thoroughly cleaned — ultrasonic vibrations dislodge contaminants from surfaces and cavities.

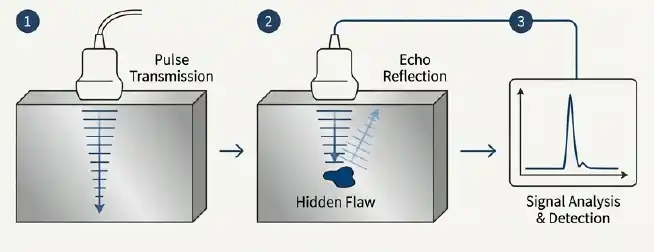

d) Non-Destructive Testing (NDT)

Used for thickness measurement and internal defect detection, this technique relies on the propagation and reflection of ultrasonic waves — without causing any damage to the part under inspection.

Advantages of Ultrasonic Technology

- Extremely high process accuracy

- Faster operation compared to conventional methods

- Reduced energy consumption and lower operational costs

- Extended equipment lifespan due to minimal heat and friction

- High safety level for both operator and environment

These advantages have made ultrasonx systems the preferred solution in many advanced manufacturing and processing facilities.

Limitations and Challenges

Despite its significant benefits, ultrasonx technology faces several limitations:

- Relatively high initial equipment cost

- Limited effectiveness on very hard or structurally complex materials

- Requires expertise in frequency control and tuning

- For certain applications, the work surface must be perfectly clean to maintain efficiency

Nevertheless, these challenges are generally manageable through proper system design and operational training.

The Role of Ultrasonic in Modern Industry

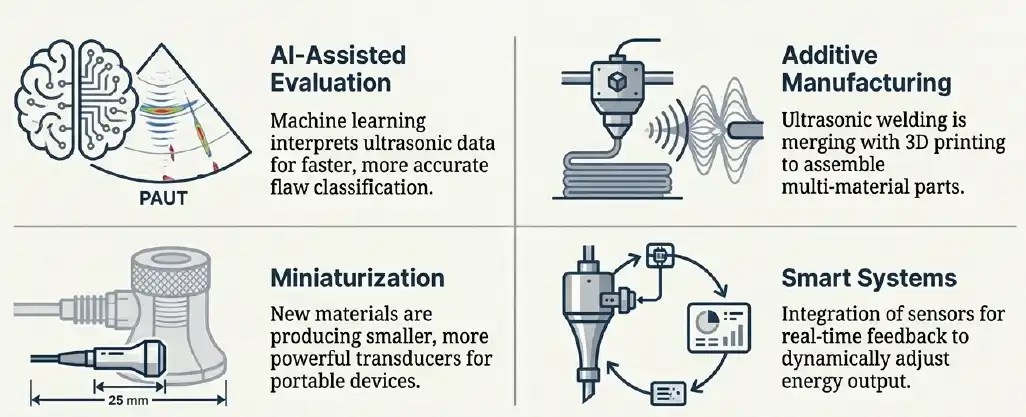

Ultrasonic have become a cornerstone of industrial automation. Today, they serve as standard solutions in automotive, electronics, packaging, food processing, and medical production lines.

Their compatibility with sensors and intelligent control systems has made them an essential element of Industry 4.0 — enabling faster, more precise, and more energy-efficient manufacturing.

Conclusion

In summary, ultrasonx technology represents the fusion of science, engineering, and innovation to enhance precision, efficiency, and safety across industrial processes.

Its strong presence in welding, cleaning, non-destructive testing, and precision manufacturing has driven most modern factories toward adopting ultrasonic systems.

Every day, new applications for these invisible waves emerge — shaping a future where advanced production simply cannot exist without ultrasonics.