Ultrasonic technology has evolved from a niche scientific curiosity into a cornerstone of modern manufacturing, diagnostics, and environmental solutions. By harnessing sound waves above the threshold of human hearing (greater than 20 kHz), engineers and scientists have developed a wide range of ultrasonic applications across industries as diverse as aerospace, automotive, healthcare, and energy.

This article examines the fundamental principles behind ultrasonic systems and explores how their versatility drives innovation in inspection, cleaning, welding, machining, sensing, and medicine.

1. Fundamentals of Ultrasonic Technology

At the heart of most ultrasonic systems is the piezoelectric transducer, which converts electrical energy into mechanical vibrations and vice versa. When high-frequency AC voltage is applied to a piezoelectric ceramic (often PZT – lead zirconate titanate), it vibrates at ultrasonic frequencies.

These vibrations produce mechanical waves in the surrounding medium — air, water, or solid matter — enabling different industrial processes depending on the frequency, amplitude, and coupling method used.

Ultrasonic applications generally fall into two broad categories:

- High-power ultrasonics (low frequency) — typically 20–100 kHz, used for welding, cleaning, and machining.

- High-frequency ultrasonics (diagnostic/inspection) — ranging from hundreds of kHz to several MHz, used in precision measurement, flaw detection, and medical imaging.

2. Non‑Destructive Testing (NDT) Applications

One of the most established ultrasonic applications is Non‑Destructive Testing — a set of methods for evaluating the internal integrity of materials without causing damage.

How It Works

An ultrasonic pulse is transmitted into a material; reflections from internal features (flaws, inclusions, corrosion) are detected and analyzed.

Key Techniques

- Pulse‑Echo: uses the same transducer to send and receive signals.

- Through‑Transmission: uses separate sender and receiver.

- Time‑of‑Flight Diffraction (TOFD): measures arrival times of diffracted waves.

- Phased Array Ultrasonics (PAUT): electronically steers and focuses ultrasonic beams.

Industries Served

- Oil & Gas Pipelines: corrosion mapping.

- Aerospace: composite delamination detection.

- Automotive: weld inspection.

- Power Generation: turbine blade integrity checks.

The precision and reliability of ultrasonic NDT make it superior to alternatives like radiography for many applications, especially when safety and in‑field portability are critical.

3. Ultrasonic Welding Applications

Ultrasonic welding relies on high‑frequency mechanical vibration to create solid‑state or molecular bonds between components.

Principle

A piezoelectric transducer generates vibrations at 20 kHz or 35 kHz, which are amplified and delivered to a workpiece via a horn. The vibration causes localized heating and material movement at the joint interface, creating a durable bond without added adhesives or extensive heat.

Use Cases

- Plastic Welding: automotive dashboards, medical disposables, electronic housings.

- Metal Welding: battery tabs, thin foil layers, aluminum to copper connections.

- Textiles: sealing of synthetic fabrics without stitching.

Advantages include clean joints, rapid cycle times, and minimal material distortion — all reasons why ultrasonic welding continues to expand in automotive, electronics, and healthcare manufacturing.

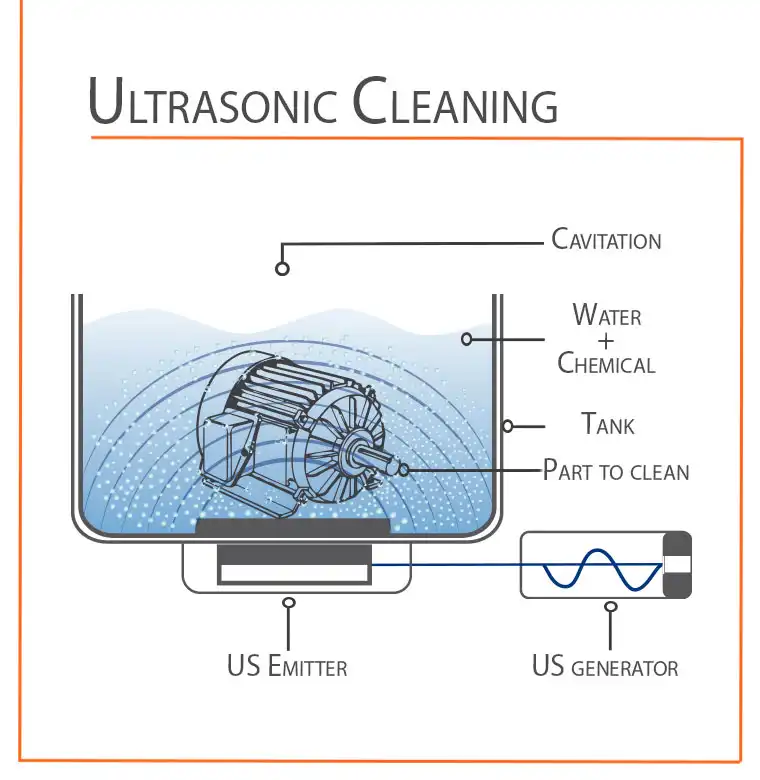

4. Ultrasonic Cleaning Applications

Ultrasonic cleaning is one of the most visible and successful ultrasonic applications in diverse industries.

Principle

High‑frequency sound waves in a liquid produce rapid alternations in pressure, generating microscopic cavitation bubbles. When these bubbles collapse near a surface, they release microjets of energy that remove contaminants.

Typical Uses

- Precision Optics: removing residue from lenses and mirrors.

- Jewelry: deep cleaning of delicate items without abrasion.

- Aerospace: degreasing ball bearings and engine parts.

- Laboratory Glassware: ensuring chemically clean surfaces.

- Mold Maintenance: cleaning injection molds to prolong service life.

Benefits include reduced chemical usage, faster turnaround, and the ability to clean complex geometries unreachable by manual methods.

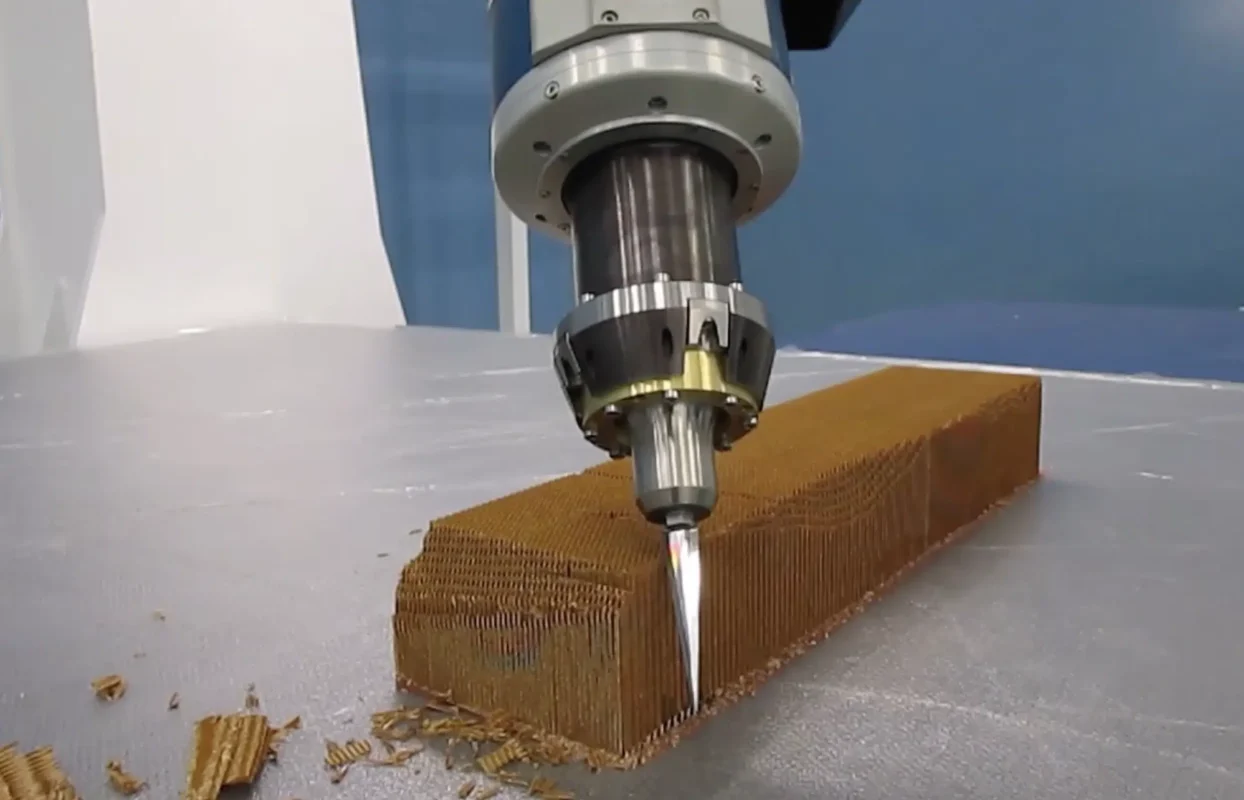

5. Ultrasonic Machining and Cutting

In materials processing, ultrasonic vibrations have been adapted for machining and cutting applications where conventional methods cause too much heat or mechanical stress.

Process

A tool, vibrated ultrasonically while loaded with abrasive slurry, gradually removes material through micro‑chipping.

Examples

- Ceramics and Glass: precise drilling and shaping without cracking.

- Hard Alloys: machining of tungsten carbide.

- Food Industry: ultrasonic knives produce clean, residue‑free slices in confectionery or bakery products.

Ultrasonic machining keeps cutting temperatures low, preserving material properties and reducing post‑processing.

6. Ultrasonic Flow Measurement and Sensors

Ultrasonic sensing extends beyond solids into fluid measurement and environmental monitoring.

Flow Measurement

Transit‑time and Doppler ultrasonic flowmeters measure fluid velocity without penetrating the pipe — critical in clean water management, chemical processing, and heating/cooling systems.

Other Sensors

- Level Measurement: for storage tanks and reservoirs.

- Proximity Detection: in robotics and automotive parking assistance.

- Gas Leak Detection: detecting ultrasound generated by escaping gas.

These contactless measurements improve reliability and reduce maintenance.

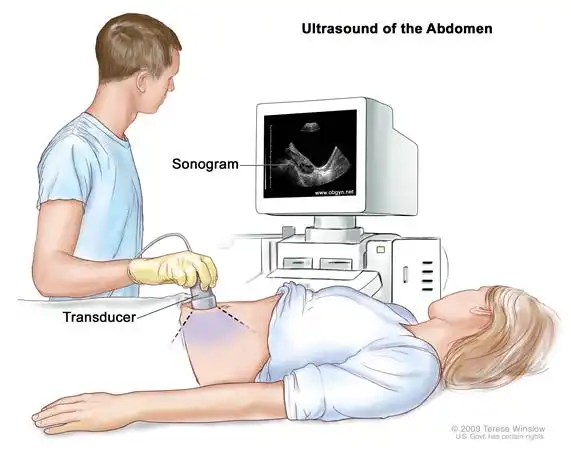

7. Medical and Biological Applications

Medical ultrasound has become almost synonymous with non‑invasive diagnostics.

Diagnostic Imaging

- Obstetrics: real‑time fetal imaging.

- Cardiology: echocardiograms for heart structure and function.

- Musculoskeletal: detecting tendon and ligament injuries.

Therapeutic Ultrasound

- Physiotherapy: deep tissue heating.

- Lithotripsy: breaking apart kidney stones using focused shockwaves.

- Targeted Drug Delivery: using ultrasound to temporarily increase cell membrane permeability.

Biological Research

Ultrasonic disintegrators are used to break cells for genetic or biochemical analysis.

8. Emerging and Future Applications

As technology evolves, so do ultrasonic applications.

- Ultrasonic Additive Manufacturing (UAM): bonding thin metallic foils layer by layer.

- MEMS Ultrasonics: tiny ultrasonic sensors for autonomous vehicles.

- Environmental: ultrasonic algae control in reservoirs.

- Non‑contact Energy Transfer: powering small implantable medical devices wirelessly.

- Advanced Diagnostics: high‑resolution 3D ultrasound imaging.

Future developments will likely focus on miniaturization, software integration, and eco‑friendly design.

9. Advantages and Limitations

Advantages

- Precision and control.

- Non‑contact energy transfer.

- Cleaner processing with reduced chemicals.

- Faster cycle times.

Limitations

- Limited penetration in coarse‑grained or attenuative materials.

- High‑power systems can be costly.

- Coupling medium needed in many applications.

10. Conclusion

From ensuring aircraft safety to producing ultra‑clean surgical instruments, ultrasonic applications have transformed how industries operate. Their adaptability across inspection, bonding, cleaning, cutting, sensing, and medicine underscores their role as a foundational technology of modern manufacturing and diagnostics.

As ultrasonic systems become smarter and more efficient, ULTRASONX is committed to designing and delivering solutions that meet the evolving needs of industry leaders worldwide.